Nancy White is the content marketing manager for the Corporate Brand team at PTC. A journalist turned content marketer, she has a diverse writing background—from Fortune 500 companies to community newspapers—that spans more than a decade.

Editor's note: This blog was originally published in 2019 and updated in January 2024.

What is a digital transformation strategy?

A digital transformation strategy is a detailed plan for using digital solutions to improve the physical aspects of your business across engineering, manufacturing, and service. Digital transformation (DX) is, in and of itself, a broad business strategy. Developing a roadmap for short- and long-term digital transformation, guided by business outcomes, not technology, is the essential foundation.

Companies of all sizes are seeing enviable business outcomes from digital transformation efforts, such as improving efficiency, maximizing revenue growth, and reducing operational costs. In fact, a survey of industry professionals found that 92 percent of companies are already pursuing digital transformation. However; the survey also revealed there were various stages of maturity—and success.

Why is developing a digital transformation strategy important?

Creating a digital transformation strategy is important because it ensures that there is an impactful, measurable, and concerted effort toward key business goals. Any team can engage in digital transformation initiatives, but it's not going to move the needle for a business unless there is a coordinated and strategic initiative.

Digital transformation is often complex, involving multiple departments and impacting the daily tasks of employees; it takes time, communication, and collaboration, to be successful.

Who should be involved when creating a digital transformation strategy?

Developing a digital transformation strategy is a collaborative process that needs to have representation from ideally all of the involved groups.

One of the keys to successful digital transformation is nurturing a company culture that’s innovative, collaborative, and inclusive. Internal buy-in from multiple levels and functions of the company is necessary. Research shows that pursuing the cross-functional change that can achieve transformational impact requires both a top-down and bottom-up approach. In fact, our research revealed that ROI is two to three times more likely to exceed expectation with this approach.

Below is an overview of the leaders and teams most involved in the strategy.

-

C-suite: Executives need to buy-in to digital transformation and provide the vision—in other words, the why—to the organization. They’re not just allocating budget, they need to ensure digital transformation efforts are aligned to the long-term strategy and goals of the organization. The most common executive roles involved are CEO, CTO, CIO, etc.

-

Digital transformation leader: More companies are opting to have a dedicated person and/or team to lead digital transformation. It helps with accountability, visibility, and focus within a company.

-

Cross-functional and multi-level representation: Increasingly common is a digital transformation governance body; it’s one way to ensure representation of stakeholder groups, assure a sense of ownership across functions, and provide visibility on transformation initiatives and progress.

-

Trusted partners: It’s rare to have a completely internal digital transformation; companies must rely on trusted partners and experts to support needed technologies, lend industry and process expertise, and troubleshoot execution. Choosing the right digital transformation partners, ones that are as invested in your success as you are, and share the same values and innovation goals, is a must.

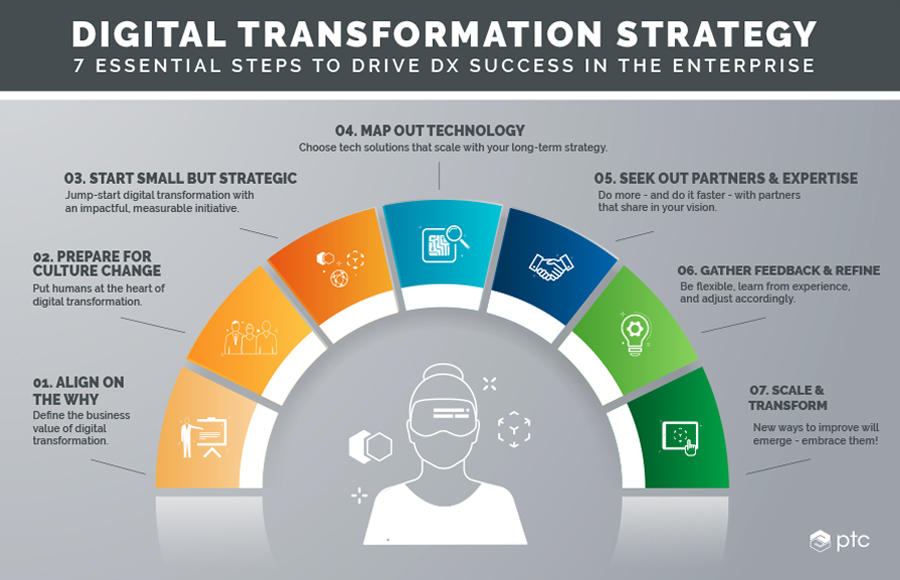

How to build a digital transformation strategy: 7 key steps

With that in mind, this article details the key steps and best practices to developing a successful DX strategy and serves as a guide as you build your strategy from the ground up:

1. Align on the Why of Digital Transformation

4. Map Out Technology Implementation

5. Seek Out Partners and Expertise

6. Gather Feedback and Refine as Needed

1. Align on the why of digital transformation

Part of the problem with the term “digital transformation” is it means many things to many people. Often leaders believe that digital transformation leads with technology and the why behind the implementation is only discussed afterward. This is a backwards approach—and one we’ve seen fail many times. To set digital transformation up for success, it’s essential to start with identifying your business needs and goals and building a strategy from there.

A great place to start is with your organization’s strategic goals—your 5- to 10-year plan for the future. This starts the discussion about digital transformation from a much different – and more effective – position than starting with the technology. In order to execute on digital transformation, there needs to be a compelling business case and clear business value identified.

This also begins the conversation at the C-suite level; something that’s an important step to the cultural shift that goes hand-in-hand with successful digital transformation. (We’ll detail more on this later.)

>>Check out The Complete List of Why Companies Are Pursuing Digital Transformation.<<

Let’s walk through an example. Volvo Group is dedicated to high-quality products and engineering excellence. With that topline vision, the next question is what can be done both short-term and long-term to make that happen? What are the use cases that are going to move the needle on this goal?

In the short-term, Volvo determined the quality assurance (QA) process was a prime target. A manual and complex procedure, the QA process required well-trained experts and was bogged down by paperwork. By injecting the right technologies, they could transform the process, show measurable results, and establish a model to bring to other factories and applications.

Bottom line: Digital transformation isn’t a one-off project or initiative, it’s something that strategically positions your company for the future. Create a foundation for digital transformation out of business priorities and defined business value.

2. Prepare for culture change

As we mentioned above, C-suite support and enthusiasm for digital transformation is critical to the cultural change that must happen within the organization over time. Over the past three years, digital transformation has shifted to almost exclusively (90 percent!) being overseen by C-suite; PTC's annual State of Digital Transformation report confirmed that the CEO, CIO, CTO, etc. were all part of DX strategy and budget ownership. This is up from just 36 percent in 2019.

It’s natural for there to be resistance to change and skepticism of the “new” so be prepared to address that push-back. Thinking beyond the C-suite, developing a team mindset with representatives across the value chain—from IT, OT, sales, marketing, design, and more – serves as the start of a strong governance that will execute on the digital transformation strategy. Having a core team of “cheerleaders” that understands the vision behind an organization’s digital transformation will pay dividends long term.

Keep in mind that any transformation will have challenges along the way; leaders need to nurture a culture where everyone learns from mistakes and builds upon successes.

Bottom line: As digital transformation initiatives roll out, it will affect the work employees do daily. Identifying projects that truly improve the efficiency, effectiveness, or productivity of workers (at any level) is a critical piece to digital transformation.

3. Start small, but strategic

Digital transformation is a journey, not an event, and identifying the first “proof-of-concept” project is crucial. It’s what will set the stage for future initiatives—and help get buy-in from leaders and teams. Nothing changes overnight; it takes time to make progress. There are two essential characteristics to the right project—quantifiable and accelerated time-to-value.

Why? Proving ROI in a short time frame gives the digital transformation momentum. There may be project that could have a sizeable ROI but could take a year or so to implement. The best starting initiatives are “quick wins” that can be up and running—and show measurable results within six months or less.

One successful approach, with manufacturers in particular, is to take think about digital transformation projects as “modular.” For example, a project that can be piloted in a single factory and – after demonstrating initial proof-of-value—scaled quickly to more factories and operations. This approach presents the opportunity for value to be multiplied quickly.

Bottom line: The first digital transformation initiative is critical to proving value and ensuring the long-term success of your strategy. Take the proper steps and time to identify an impactful way to jump start your DX efforts.

4. Map out technology implementation

There's a formula for unsuccessful technology-driven digital transformations:

New Technology + Old Operations = Expensive Old Operations

What it means is if you don’t change the processes and cultures of our company, your employees are just enabled by expensive new things.

That’s the reason why we’re already at the fourth tenet and are just now delving into technology side of digital transformation. Just to drive the point home, successful digital transformation doesn’t start with technology—it starts with business strategy.

With the foundation established in the first three steps, technology becomes a necessary tool, or lever, to help you reach the desired and defined business outcomes.

A common set of DX technologies fundamental to achieving digital transformation includes:

These include:

- Mobile

- IoT

- Digital Twin

- Robotics

- Cloud

- Artificial Intelligence & Machine Learning

- Augmented Reality

- Additive Manufacturing

One or more of these technologies may be necessary to achieve your initial DX use cases. Some of them may already be in use in your organization, but there are missing pieces preventing real business value from being realized.

With most technology pursuits, outside vendors are necessary (read more about the downside of DIY approach) and should be chosen with a long-term strategy in mind. Finding partners with the right combination of product and expertise often accelerates time-to-value.

Bottom line: Developing a clear roadmap with technology for initial and future initiatives is an essential building block to digital transformation success.

5. Seek out partners and expertise

When examining options for technology and technology partners, bear in mind the future vision. Key questions to ask:

- Will the technology and vendor support scaling?

- Does the vendor and team share a similar vision for digital transformation?

- Will they be able to support you in your long-term strategy?

- How does it integrate with your existing technology?

- Do they have the right technology and expertise for your specific use cases and industry?

- What results have they achieved with similar use cases/applications and with similar companies?

You can have the most perfect technology but not the right partner to implement it. Industry expertise is a critical elements; if the people helping you don’t have the experience, knowledge, and background in your application, there will be struggles. Those with expertise have learned from previous clients all the things not to do – and that’s very valuable as you execute on your digital transformation strategy.”

Another aspect to this step is avoiding “spot solutions”—in other words, a technology that solves one department’s pain point but is not the right technology or solution to scale across the enterprise. Having CXOs involved in DX tech decision-making helps ensure the company-wide strategic vision is not lost.

Look for partners that complement, augment, and enable your digital transformation vision; at PTC we have a vibrant partner ecosystem to ensure our customers have both solutions and expertise to guide them. Strategic partnerships, like the ones PTC has with Microsoft, Rockwell Automation, and Ansys, brings a definitive advantage to our core technologies and our customers.

Bottom line: Look to strengthen your core competencies by seeking partners who complement your strengths and understand your business. Finding partners that will accelerate results and drive initiatives forward is critical to achieving digital transformation outcomes.

6. Gather feedback and refine as needed

At this point, we have a vision and a broad-based coalition that supports it, a strategic use case, a technology roadmap, and partners in digital transformation success. Before moving ahead full-throttle, clearly define key performance indicators (KPIs) for each project. Make sure all parties are aware and accountable to what needs to be delivered to call the project a success.

At the same time, create a strong feedback loop with stakeholders to ensure everyone is learning from the experience as the digital transformation strategy unfolds.

Understanding that digital transformation is a journey, teams need to set “waypoints” is a means to check in with the progress, adjust, and improve.

New objectives may come along—and that’s OK. Technologies should be flexible and agile enough to respond. With digital transformation, you’re never locked into a physical box.

Bottom line: One of the hallmarks of an organization undergoing a digital transformation is agility. Putting in place a strategic roadmap is essential but being willing and capable to adjust according to results is the ultimate path to success.

7. Scale and transform

By now, your company is beginning to see results from the initial use cases outlined in the digital transformation strategy. Leverage this success to gain momentum and generate collaboration around the next steps, as well as long-term strategy.

As digital transformation progresses, new ways for digital to transform physical emerge. Consider opportunities to scale horizontally—by applying similar strategies to multiple locations – and vertically by connecting additional technologies.

Bottom line: Transformation looks different at every organization, that’s what makes the digital transformation strategy so important. It’s a personalized roadmap of where change is most effective with your organization.

What are the key trends for digital transformation?

Like the organizations that engage in digital transformation, digital transformation itself must evolve over time. As we discussed above, there’s no end game for digital transformation; it’s an exercise in constant growth and change.

For 2024, many organizations have been engaged in digital transformation for years, yet with competitive global markets, and evolving workforce, and emerging technologies, there’s still work to do:

1. More investment in digital transformation

According to IDC, global spending on digital transformation is expected to reach $3.9 trillion in 2027. The long-tail effects of the COVID-19 pandemic, where many companies realized just how much digital technologies increase organizational resilience in the face of market disruption, has led to increased investment.

Discrete and process manufacturing, IDC forecasted, will make up about 30% of worldwide spending on digital transformation. That means, if you’re in those industries, you need to be focused on how digital transformation initiatives can help increase revenue and/or create efficiencies—because your competitors are.

2. Focus on AI and machine learning

The year 2023 may become known as the Year of AI. But, truthfully, it’s been a huge opportunity and pursuit for many companies for many years. However, the use cases are more specific, and technologies are more sophisticated.

Industrial companies will be zeroing on the AI and machine learning use cases that best serve their company and customers in 2024. In particular, companies will be looking at how to do more with their data and analytics engines.

3. Spotlight on process transformation over technology

It’s no secret global companies are facing challenges caused by dynamic supply chains, distributed workforces, and increasingly competitive landscape. While digital technologies are often needed for transformation, process plays a key role in driving ultimate success.

In 2024, companies need to take a fresh look at how their teams operate. Are they collaborating effectively? Are they able to iterate quickly? Are they delivering value incrementally? Are they able to respond to change well?

While software development has fully embraced Agile over the past two decades, the principles are just now being embraced by physical product development. Companies that do successfully implement Agile product development are seeing benefits like: more effective collaboration across distributed teams, reduced levels of risk through greater transparency and internal communication, and improved time to value.

4. Leveraging digital technologies for sustainability goals

For many industrial companies, digital transformation efforts often can align business and sustainability goals. environment. For example, if a factory is more efficient, it likely will use less energy. If a product uses less materials, it costs less to manufacture and ship. If a product is higher quality, it will have a longer useful life.

Due to increasing regulations and market pressures, we’ll see more businesses using digital technologies to lower their carbon emissions and deliver more visibility into their environmental impact.

For more on these trends, check out our 7 Digital Transformation Predictions for 2024.

Final thoughts

One of the misconceptions about digital transformation is it’s a destination – once we do ‘x’ or achieve ‘y’ we’ll be done with it and move on to something else. As industry and business evolve, digital transformation – converging the physical and the digital – will continue to be a critical part of business strategy in order to remain competitive, differentiate products and services, and drive efficiency.