Editor's Note: This post was originally published in 2017, it was updated in Jan. 2023.

The term “design intent” is used a lot when talking about product development, but what does it really mean? Is it simply “what I intend my design to do,” or is there a deeper meaning? When it comes to parametric modeling, design intent takes on a valuable role toward improving model quality and adaptability.

What Is Design Intent?

Design intent is a method used in computer-aided design that defines relationships between objects, so that a change to one propagates automatically to others. While useful in many product design applications, design intent plays a primary role in reverse engineering, which is a process where measurements are taken from an existing part and used to create a CAD model for record keeping, design modifications, etc.

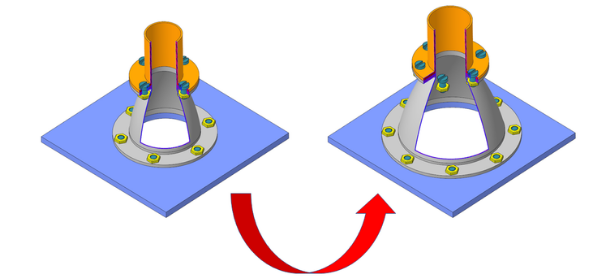

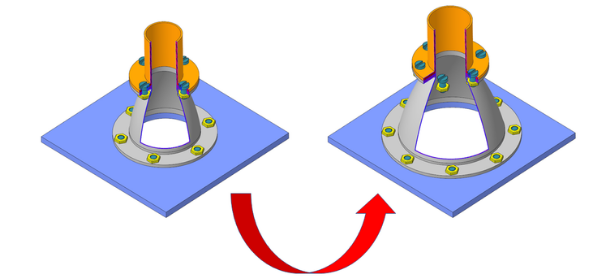

In the following example, a pipe reducer assembly is controlled by three critical parameters: the inlet diameter, the outlet diameter, and the reducer height.

When the inlet diameter and outlet diameters increase, the hole in the plate and pipe, the sizes of the flange, and the bolt circle diameters increase as defined by our design intent. When the height of the reducer increases, the location of the pipe updates accordingly.

In addition, the number and spacing of the bolts increases automatically with larger diameters to ensure adequate clamping force.

(Note, a section cut has been applied to the reducer and pipe for clarity. The bolts and nuts were excluded.)

Typically, design intent is associated with parametric modeling. Other modeling approaches (such as direct modeling) might focus on speed of modeling or minimizing the number of objects in the model.

And while these different approaches and design intent aren’t necessarily mutually exclusive, design intent typically requires more effort and time in the initial design phase. However, this additional work in the beginning results in significant time and financial savings when product requirements inevitably change, especially in complex assemblies with numerous interdependencies.

What's New in Creo

Explore what's new in Creo 11 to take advantage of premium features and enhancements.

What's New

Building in Design Intent

Methods for implementing design intent can range from the relatively simple, like the selection of the correct dimensioning scheme, to the moderately advanced, like top-down design, to higher levels of complexity, like embedding optimization routines directly into the model’s regeneration cycle.

Below are some ways you might consider building design intent into a CAD model.

Designing Sketches and Features

Sketches form the basis for many features in parts, especially those that tend to add or remove the most material in parametric models. The dimensioning scheme in the sketch determines how its subsequent feature will move when you change earlier features in the part. For example, take this simple part:

Depending on how you locate the cylindrical feature, changing the width of the base feature could result in the following possibilities:

The takeaway? When you choose the dimensioning scheme of the cylinder based on how it should react to changes in other features, that’s design intent.

Designing Parts

At the part level, the type of feature you select determines how that feature can be changed in the future. Take the example of creating a cylinder. There are easily half a dozen different ways in which that feature can be created.

A simple cylinder can be created in a number of ways, each with consequences to your product design:

- An extruded feature might give you the best control over the depth of the feature.

- A revolved feature would be preferred if the angle of revolution is most likely to change.

- A swept feature is best if you expected the path or direction of the feature to change.

- A blended feature would be the way to go if controlling the shape at the ends and internal locations was paramount.

- Advanced surfacing techniques like boundary blends and style surfaces provide even higher levels of adaptability to change.

Ways a cylinder might evolve in a design.

Designing Assemblies

At the assembly level, the most effective method of building with design intent is through top-down design. This methodology employs special kinds of models called skeletons to consolidate important geometry that affects multiple components, and then distributes that design information to components using data-sharing features.

Critical parameters and dimensions can also be defined in digital engineering notebooks and shared with other models. You then write equations to drive your models from the notebook.

Later, when you need to implement a radical design change, rather than opening and modifying dozens or hundreds of individual parts, changes to the skeleton and/or notebook are propagated to all connected models.

Designing Products

At the product level, we can extend the concept of design intent further to the way we think about new technologies—such as smart, connected product design (aka the Internet of Things or IoT) and augmented reality (AR).

Smart, connected products use sensors, transmitters, antennae, and even microcomputers to connect to the internet. That means your products can send information back to your company about how they're being used. Someone who is accustomed to designing intent into a model will naturally plan for this new data. For example, you might create products that can easily and remotely onboard software updates and add new capabilities to products in the field in response to incoming IoT data. In fact, Tesla famously did just that a few years ago when it issued an over-the-air repair to their cars.

Using AR, a tablet overlays digital data on a physical airplane.

Augmented reality, which adds digital information to real-world scenes, offers opportunities for developers to further prepare for future changes. For example, imagine replacing part or all of a product’s user interface (UI) with AR. You could simplify the product by removing buttons, touch screens, and indicators. Then, when new capabilities are added, the UI can be updated accordingly. Everyone carries around smart phones with cameras—why not turn that into your product’s UI?

A virtual dashboard for an automobile

A crucial aspect about IoT and AR is that we can update and improve our products after they’ve been shipped, without the customer needing to return the product. This dovetails perfectly with the core tenets and evolution of design intent: empowering ease, speed, and power of change, through both physical and digital design.

Design intent is all about making smart choices during the product development process. The more thinking you do up front, the fewer problems you have later on. The only constant is change. By planning for it, you create models that are flexible, robust, and adaptable. Understanding and applying design intent improves the quality of your modeling and results in more intelligent products and better customer satisfaction.

Up Next

Keep Up With CAD

Get the latest tips, insights, and news. Subscribe to the PTC Express newsletter today!

Subscribe Now