David Immerman is as a Consulting Analyst for the TMT Consulting team based in Boston, MA. Prior to S&P Market Intelligence, David ran competitive intelligence for a supply chain risk management software startup and provided thought leadership and market research for an industrial software provider. Previously, David was an industry analyst in 451 Research’s Internet of Things channel primarily covering the smart transportation and automotive technology markets.

Manufacturers are recognizing the world is changing around them and the need to change with it is only growing. Facing mounting threats, such as digital disruption and global competition, these manufacturers are increasingly turning to IIoT as the cornerstone of their digital transformation initiatives. Surveys show it’s critically important to achieving manufacturing business strategy; in fact, IDC forecasts that manufacturing IoT spend will nearly reach $200 billion this year alone.

We’ve narrowed down the top benefits of IoT in manufacturing to these three areas:

- Improvement of operational performance

- Ensuring safety and compliance

- Increasing flexibility and agility

Let's take a look at each:

Operational Effectiveness Through Operational Intelligence

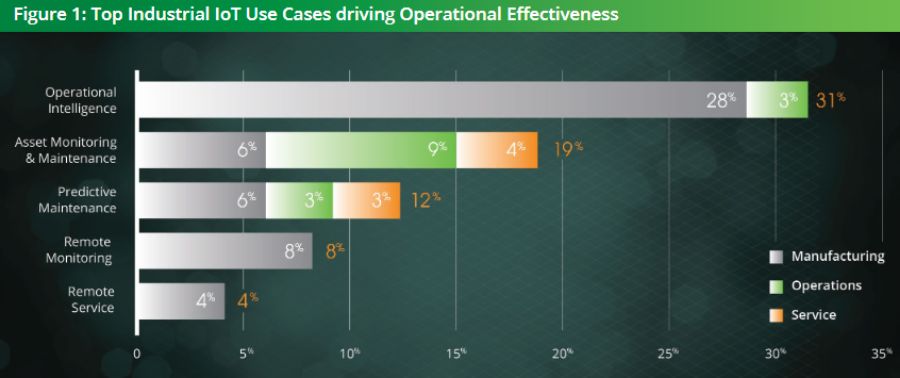

Manufacturers are implementing IIoT across their entire operations, ultimately achieving operational intelligence - the top use case in our latest State of Industrial Internet of Things report.

This ‘IIoT intelligence’ enables end-to-end visibility of the supply chain including extensive multi-site deployment views via encompassing IIoT platforms capable of contextualizing real-time plant efficiency KPIs (overall equipment effectiveness, direct material costing, product quality etc.) and managing a specific plant’s equipment and assets, down to the operator and workcell-level.

The main IIoT use cases driving several operational effectiveness outcomes (i.e. increased productivity, improved plant efficiency, asset uptime and quality, reduced operational risks, overhead costs, and changeover times) are predictive and increasingly preventative maintenance. This imperative shift away from reactive maintenance systems, which are subject to error from nondigitized historical information, tribal knowledge, and lack of industrial connectivity into assets, is increasingly accessible via the IIoT.

With a centralized IIoT platform and analytics, data feeds from traditionally black-boxed legacy machines and equipment are now accessible through connectivity into industrial protocols, OPC servers, on-site manufacturing software-driven systems (HMI, SCADA, MES), and further contextualized with crucial business systems (ERP, CRM).

IIoT analytics fused with machine-learning identifies anomalies in asset health data to predict failures, potential downtime, and determine the root cause of a failure to prevent future ones. High-value industrial assets are leveraging IIoT data with simulation to create prescriptive digital twins. Augmented reality is also proving a useful technology for capturing domain knowledge of front-line worker workflows interacting with industrial equipment, lessening skill gap concerns.

IIoT interlinking these systems drives a critical metric for manufacturers called operational equipment effectiveness (OEE); data-driven predictive insights into assets improves availability (reduced equipment failure, set-up/changeover time), performance (reduced idling, stopping), and quality (fewer defects, reduced cycle times).

Hirotec and Woodward are both great examples of IIoT bridging these many disparate systems to drive operational efficiencies.

Ensuring Safety and Compliance

Compliance with OSHA standards is a high operating expense on manufacturers’ financial statements; traditional regulation procedures are timely and costly. This compliance bottleneck is primarily due to reporting systems not being digitized; the IIoT is the natural solution for connecting these disparate sources of information currently residing in silos and hitting stringent compliance frameworks. A connected system can feed relevant data for manufacturing plant risk assessments, work scheduling systems, and inspection reviews.

Creating both a naturally safer environment for workers and abiding by health, safety, and environment laws is attainable via the IIoT. Some manufacturers require verification that assets are in constant compliance, where IIoT and real-time monitoring plays a crucial role. This is even more vital in certain manufacturing verticals subject to specific regulatory frameworks, such as food and beverage process manufacturers who must abide by FDA laws. Energy management is also a major expense and opportunity for optimization for manufacturers via IoT and complying with governmental energy usage laws.

Increasing Flexibility and Agility

Meeting the constantly changing demands of customers is pushing manufacturers to become increasingly flexible and agile across their shop floors. Two-thirds of manufacturing CEO survey respondents claim, ‘acting with agility is the new currency of business; if we’re too slow, we will be bankrupt”.

Industrial machines and robots need to be easily reprogrammed and updated to adhere to these shifting and increasingly customized customer requirements. Bi-directional connectivity through IIoT enables a seamless link with industrial assets with IIoT platforms providing the HMI tailored for a variety of roles – ranging from the CXO to front-line worker.

How Could IoT Benefit Your Manufacturing Operations?

Streamlining these manufacturing processes with IIoT drives operational efficiencies benefitting further downstream including supply chain optimization. Seemingly minute percentage changes of operational improvement through IIoT can generate thousands in cost savings and productivity, with a cascading effect throughout the supply chain and the manufacturer’s elevated position in the competitive landscape.