Cat McClintock contributes to the Creo and Mathcad blogs for PTC. She has been a writer and editor for 15+ years, working for CAD, PDM, ERP, and CRM software companies. Prior to that, she edited science journals for an academic publisher and aligned optical assemblies for a medical device manufacturer. She holds degrees in Technical Journalism, Classics, and Electro-Optics. She loves talking to PTC customers and learning about the interesting work they're doing and the innovative ways they use the software.

Any good design engineer keeps up with new ideas to create high-performing, cost-effective products. Especially if they worry about staying competitive. Nobody wants to be the guy who thought interchangeable parts or blow molding were passing fads.

You probably already know that additive manufacturing has found a place in product development recently, allowing for quick one-off or small batch fabrication. In fact, you may use the machinery in your company today for prototyping, jigs, or even spare parts.

As for generative design, this cutting-edge technology hasn’t reached many designers yet, but it’s promising to revolutionize everything we thought we knew about how products should look and feel.

Put the two together, however, and that’s when things get really interesting.

What Is Generative Design?

Generative design is a technology that automatically creates optimized designs based on the engineering and operational constraints you set. It draws power from your desktop computer or the cloud to offer up dozens - or even hundreds - of options that meet your criteria.

Imagine that you want to minimize the mass of a part, without compromising its performance. In the past, you might have shaved a wall thickness here or expanded an opening there. Now imagine a tool that can explore thousands of those alternatives within seconds, all of them meeting your requirements.

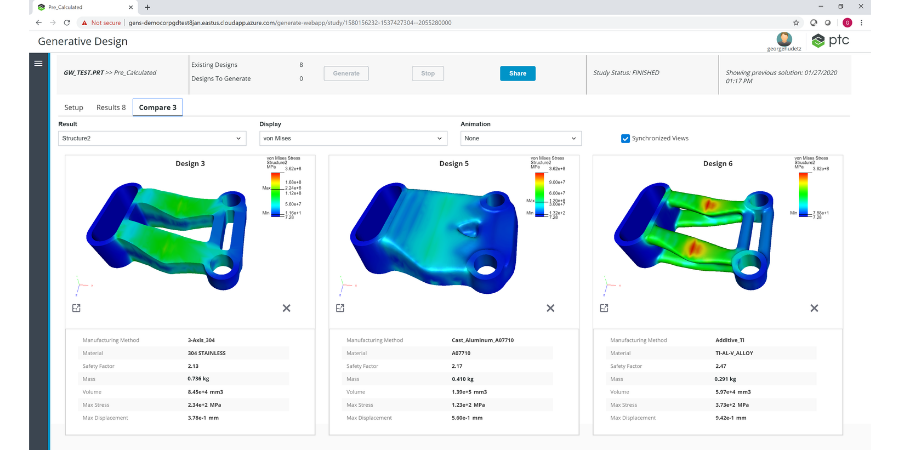

Generative design can even evaluate variants in materials and manufacturing methods, quickly converging on the options that fit your requirements.

Expand Possibilities with Generative Design and Additive Manufacturing

While generative design is sophisticated enough to work with traditional methods, additive manufacturing provides the technology the most freedom. It’s not hard to understand why.

An example of a part created via generative design. The system optimized the two designs on the left for 3-axis milling and cast aluminum. The part on the far right has been created for additive manufacturing, and therefore need fewer constraints.

With additive manufacturing, you don’t have to worry about draft angles, machine setups, etc. As a result, the generative design engine is free to explore shapes that are more organic than those produced for legacy manufacturing methods.

Plus, the material options now include more than just simple polymers. You can choose from metals, ceramics, glass, and composites. In short, additive manufacturing removes many of the constraints imposed by traditional manufacturing.

This might be useful for creating a lighter weight airplane part, a unique prosthetic limb, or even a better performing running shoe.

Generative design converging on the lightest weight design that meets requirements.

CAD Matters

The key to making these technologies succeed together lies in your CAD system.

Ideally, your generative design engine operates within your CAD system, and your CAD system communicates seamlessly with your additive manufacturing devices. That way, you have a streamlined system that produces multiple AI-driven designs, then validates your models, optimizes for successful manufacturing, etc. Plus, it’s linked to your existing products, processes, and people.

The result is nothing less than dramatic. Optimal designs you never would have ever imagined now emerge from your CAD system, ready for manufacturing, in record time. Together, generative design and additive manufacturing create opportunities that no design engineer can afford to ignore.

Get Ready to Rethink Your Designs

Excited about the future of product design? PTC plans to release its generative design solutions throughout 2020. Feel free to contact us with your specific questions.

To learn more about these and other advances in CAD, we recommend An Engineer’s Guide to CAD and the Renaissance of Product Design, available free to readers of this blog.