Cat McClintock contributes to the Creo and Mathcad blogs for PTC. She has been a writer and editor for 15+ years, working for CAD, PDM, ERP, and CRM software companies. Prior to that, she edited science journals for an academic publisher and aligned optical assemblies for a medical device manufacturer. She holds degrees in Technical Journalism, Classics, and Electro-Optics. She loves talking to PTC customers and learning about the interesting work they're doing and the innovative ways they use the software.

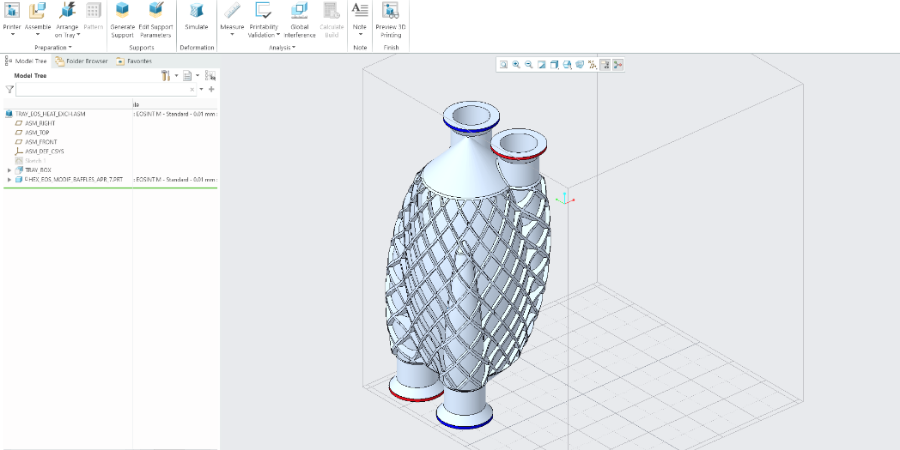

A heat exchanger designed using Creo has won the 2021 Cool Parts Showcase award for best proof-of-concept.

According to contest guidelines, the award recognizes innovative 3D-printed parts that solve a problem using additive manufacturing and are production ready.

PTC partnered with Advanced Engineering Solutions and EOS on the development and printing of the device, which is used to cool gear box oil in a helicopter.

The resulting design is half the size of its predecessor and four times as efficient.

Image: Award-winning avionics heat exchanger design.

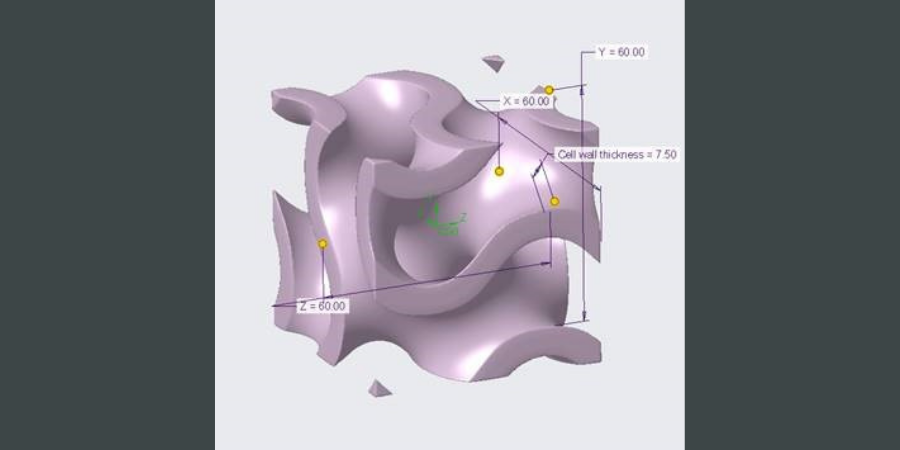

At the heart of the designs lies a compact collection of gyroid lattices, fabricated by direct metal laser sintering. Gyroids provide abundant surface area for cooling. Plus, they can support themselves during manufacturing.

Without extra support material, typically associated with additive manufacturing, companies save on material costs, post processing time, and waste.

Image: A gyroid cell, like the one in this image, can be repeated to create lattice structures that need no support during additive manufacturing. CAD systems can further apply simulation to these structures to optimize parts for weight and strength.

The technology to design gyroids in CAD became available only recently. “With Creo Additive Manufacturing Extension, we now have the capability to build these structures,” says the heat exchanger engineer, Andreas Vlahinos (pictured above), CTO Advanced Engineering Solutions. “And not only that, but we can also simulate them in real time.”

The Cool Part Showcase contest seeks out subjects for The Cool Parts Show, a video series from Additive Manufacturing magazine, and was awarded at the Additive Manufacturing Conference and Expo in Cincinnati in October 2021.

To hear Andreas Vlahinos talk in depth about the heat exchanger and its underlying technology, watch the replay of the webcast Inspired Engineering: A Revolutionary Heat Exchanger with Additive Manufacturing.