The term “CAD” usually refers to either computer-aided drafting (generating 2D production drawings) or computer-aided design (developing 3D solid models of products). However, we’re using CAD tools like Creo Parametric for more than drafting and design. We’re actually performing CAE – computer aided engineering – which incorporates analysis into product design.

CAD/CAE tools empower us to become better engineers, but what does that actually mean? Engineering involves both hard and soft skills. The hard skills involve technical proficiency around design, analysis, and manufacturing. The soft skills include more subjective qualities such as creativity and communication. Let’s look at how the most recent versions of Creo Parametric enhance these skills to make you a better engineer.

Improve Design Efficiency with Topology Optimization

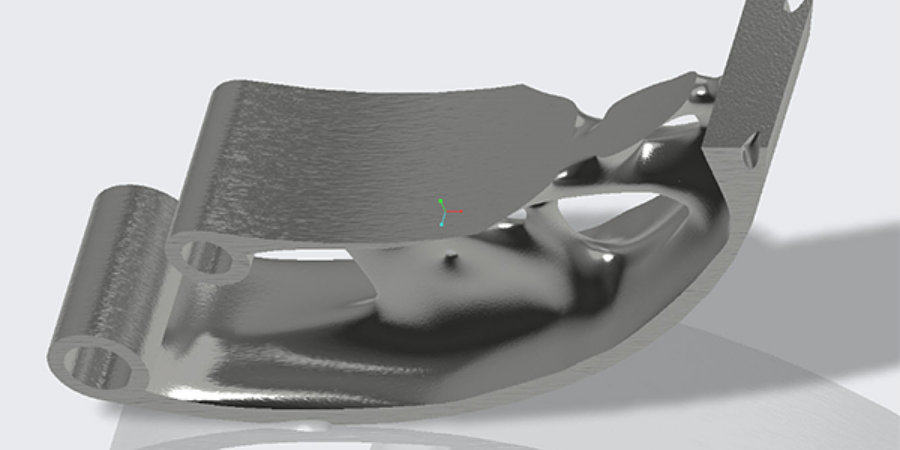

It takes a long time for an engineer to find the best solution for a product’s shape. This often means finding the least material that meets structural requirements. Standard design practices require that an engineer manually iterate over and over in a way that’s time consuming and tedious – and you could still fail to find the best solution.

Topology optimization harnesses the power of machine learning to combine analysis with design. Like structural simulation, you set up boundary conditions, then let the software find the optimal shape and mass. This powerful tool assists you in getting to the finish line quicker.

Image: Introduced in Creo 5.0, topology optimization helps you meet specifications more efficiently, often in ways that may seem unintuitive at first. Forthcoming releases of Creo will expand these capabilities further to include more powerful generative design options.

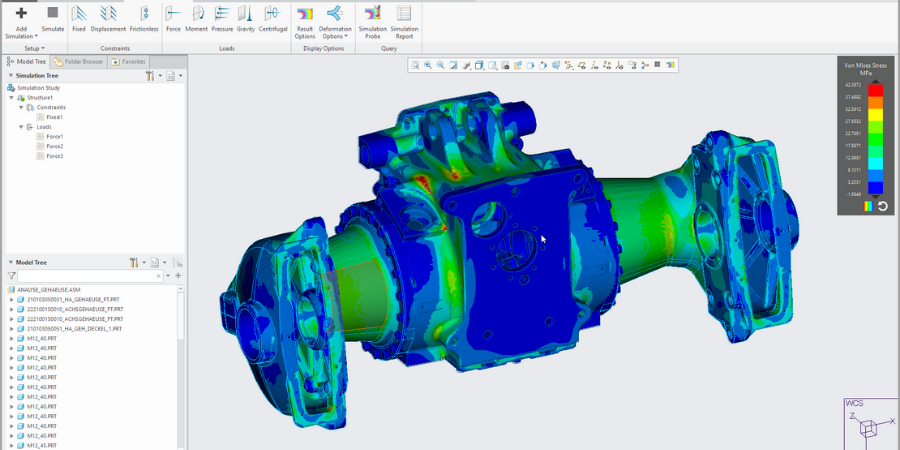

Boost Your Confidence with Real-Time Design Feedback

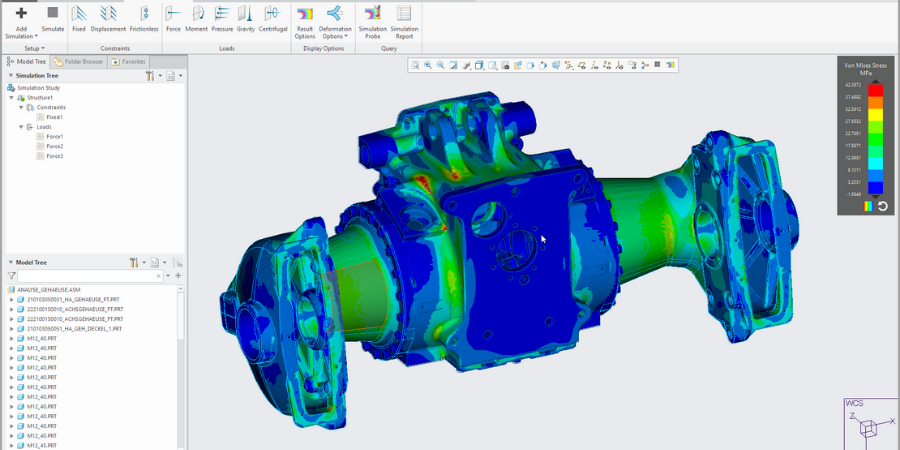

Most design engineers don’t get the benefit of feedback until their designs are nearly finished. This leads to uncertainty in design decisions, overengineering, or in some cases lost time as the team corrects problems late in the process.

However, easy-to-use tools like Creo Simulation Live, created specifically for designs, can perform structural, thermal, and modal analyses as you’re modeling. In this way, it becomes a design assistant, eliminating iterations and design cycles as you see in real-time how every design change will perform in the real world. That means you can design faster, try more ideas, and feel confident in your work.

Image: Creo Simulation Live brings real-time guidance to your CAD system, saving you time and increasing reliability in your design.

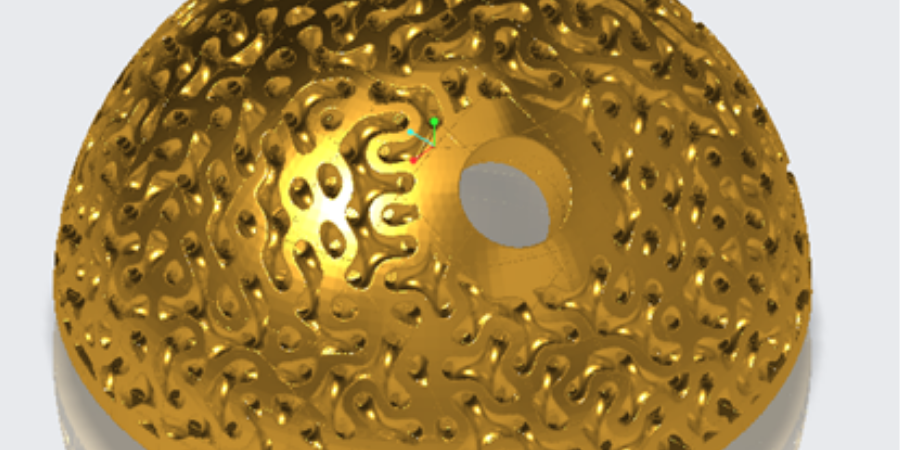

Expand Your Options with Additive Manufacturing

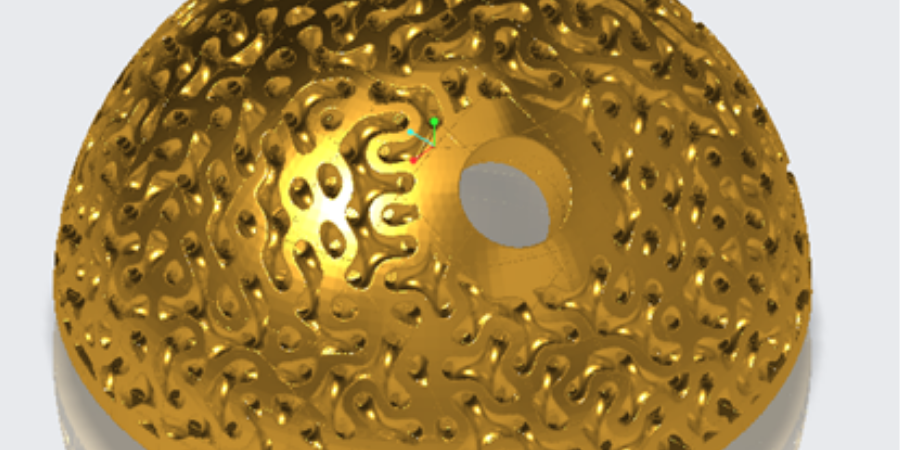

Additive manufacturing (AM) has brought new dimensions to product development by removing many of the traditional barriers to design. Your work is no longer constrained by the limitations of machining or the costs of creating molds.

With Creo, you can take your designs even further with powerful tools for creating different types of lattices, including lattice geometry designs that can minimize the need for support structures.

And to make sure your designs are light, strong, and fit for additive manufacturing, there are tools to optimize, validate, and print-check your work too. That helps ensure your products succeed on the print tray the first time you send them.

Image: Most recent versions of Creo expand your ability to use many different types of lattice cells such as gyroids, stochastic foam, or conformal lattices.

Explore Freely with Sketch Regions and Subdivisional Modeling

Engineers by definition, use creativity to solve problems, and recent versions of Creo foster that creativity through sketch regions and subdivisional modeling.

By extruding or revolving sketch regions that are part of a “Master Sketch,” users can lay out their ideas quickly in a single feature, rather than spreading design information across multiple features in different locations.

Subdivisional modeling is the equivalent of clay modeling technique in Creo. Like other surface modeling techniques, this takes you beyond traditional parametric modeling with explicitly defined boundaries, trajectories, and sections to let your inner artist develop aesthetically pleasing, organically flowing geometry.

Share Your Vision with Augmented Reality (AR)

CAD historically has used 2D drawings and 3D representations of objects on a 2D computer screen to represent what we want to make. Augmented reality superimposes your design concepts onto the real world, allowing you to communicate your ideas better than 2D or 3D. If a picture is worth ten thousand words, imagine the value realized from seeing how your product would look and work in the real world.

AR can also extend to process definition for work instructions on how to fabricate, integrate, operate, and perform maintenance, repair, and overhaul (MRO) steps, which is a principal component of manufacturing engineering.

Creo Now Does All That for You and More!

The right CAD software can help you improve your proficiency and capabilities as an engineer in design, analysis, and manufacturing, as well as increase creativity and collaboration. With Creo, each new release further supports you as you design more competitive and innovative products. Investigate and upgrade to Creo 6.0 to make sure you’re using the best tools to advance your work and career today and into the future.

* Co-written in part by Cat McClintock