Mike Gayette is a marketing professional and freelance writer based in North Dakota. He writes about engineering software, marketing technology, customer service, and team building. He also spends time at the local humane society as a dog walker and cat entertainer.

Editor's Note: This blog post was originally published in July 2021 and updated with new information in Dec. 2022.

Are you taking advantage of additive manufacturing (AM) yet? You should be.

The pace of AM innovation accelerates daily. The equipment is less costly and more efficient. New materials allow for parts that rival, and often exceed, the properties of those more traditionally made. And the public appetite for the 3D-printed products is growing.

Simply put, if you aren’t exploring what AM can do for your work, you and your customers are missing out. Take a look at the top 10 advantages of additive manufacturing.

1. Cost Of Entry Continues to Fall

You might think that diving into any new manufacturing method demands a big upfront capital investment, but with additive manufacturing, that isn’t necessarily true. The cost of entry for AM has consistently been falling. Industrial-quality printers are affordable and so are the common materials. Of course, specialized methods and materials cost more, but for most needs, it’s fairly easy to get into the game.

2. Save on Material Waste and Energy

The core definition of 3D printing is methodically adding material until a part is created. It starts with laying down a base layer of material, then adding subsequent layers until the part is complete. You may need to file off burrs or supports that hold up the part during printing, but the overall waste is minimal, especially compared to traditional manufacturing methods. Consolidating parts for manufacturing can also create large savings on energy and material costs.

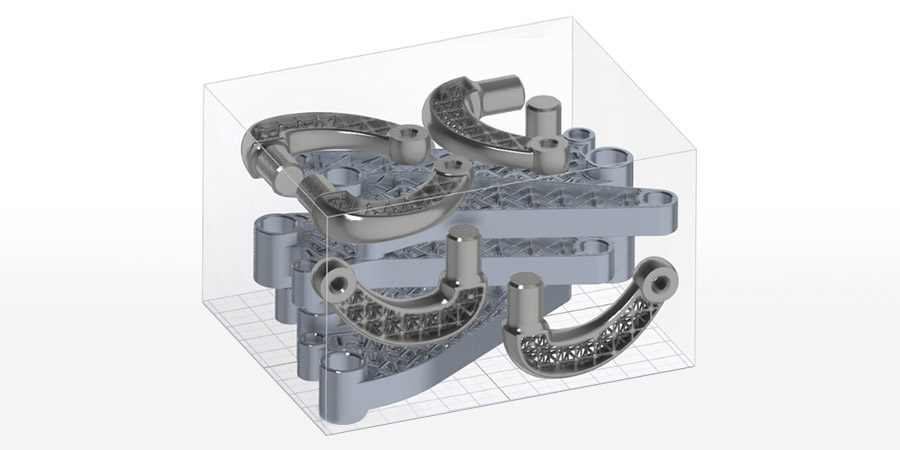

Several parts nested in a single print tray assembly save on time and material costs.

3. Save on Prototyping

Thanks to additive manufacturing, rapid prototyping is easier on deadlines and budgets. The cost for a CNC milling setup is considerable, and its subtractive process piles up material costs. The expense of an AM prototype is comparatively cheaper.

The savings add up as you test iterations using additive manufacturing. Simply make the necessary design adjustments, print the new part, and you have near-instant proof (or not) that your updated design meets the requirements.

4. Faster and Less Expensive Small Production Runs

If you need 10,000 or more of a single, basic part, it might be worthwhile to set up a mold. However, if you require only a handful of the same part, it’s likely faster to print them. Gather design files, printers, and material, and you’re all set. For lower quantity product runs, almost nothing beats additive manufacturing for speed and economy. Small-batch manufacturers have a lot to gain with AM.

3D printers manufacturing small-batch car parts.

5. Less On-Hand Inventory

Traditional manufacturing tends to stick you with a warehouse full of premade parts to draw from when you need replacements. If you have a recall or retire an old design, those unusable parts turn to scrap.

Additive manufacturing allows you to have a virtual inventory instead. You keep the part information in the cloud throughout the product lifecycle (including any updates) and then print needed parts on-demand. That removes the need for warehouse space, personnel, and piles of obsolete parts. Your CFO will thank you.

6. Easier to Recreate and Optimize Legacy Parts

Speaking of old warehouses: What if yours doesn’t have that legacy part you need? Worse, the machines that manufactured the part went out to pasture years ago. Loss of customer trust can impact repeat sales and loyalty.

AM to the rescue! As long as you have the specs or files (remember that cloud PLM?), you can almost certainly recreate it in a 3D printer. Moving toward a virtual part inventory lets you phase out the old physical inventory without having to make awkward apologies to upset end-users.

7. Improve Part Reliability

As long as you’re recreating those old parts, now may be a good time to revisit your material options. New polymers, metals, and composites become available for AM all the time. That means you can replace a part with something stronger. Recreate reliable parts as needed and save on future support calls and rework costs.

8. Consolidate an Assembly into a Single Part

Traditional, complex parts require more manufacturing steps, more material, and higher labor costs. The time to create and assemble them is longer, and it increases inventory. There’s a better way. With additive manufacturing, you can print the assembly as a single piece, saving money and time from start to finish.

With additive manufacturing you can print multiple movable parts in a single piece, potentially saving time on assembly and material.

E-book: Design for Additive Manufacturing

Get the playbook on the applications, benefits, and CAD system integration in this free e-book.

Read the E-book

9. Support AI-Driven Design Methods

Design engineers are increasingly using artificial intelligence-driven generative design to create products. Designers simply set the constraints for a part, such as dimensions, materials, and manufacturing method, and the technology then suggests a number of designs that meet those requirements. As a result, designers spend less time iterating on the perfect design, and more time engineering.

Because additive manufacturing can easily produce organic shapes, it works in tandem with generative design to make suggestions for designs few of us would have thought of on our own—while still conforming to specs.

10. Support Lattice Structures

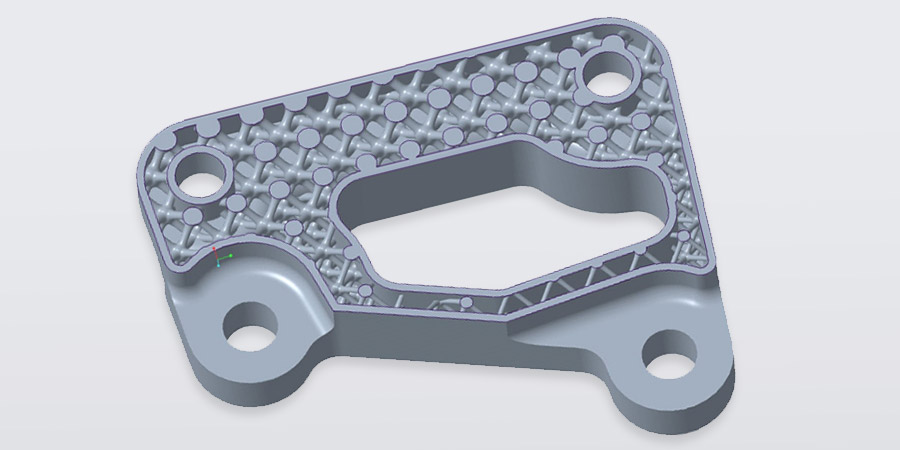

Lattices like dragonfly wings are lightweight and strong but difficult to create with traditional manufacturing methods. AM uniquely supports lattice structures that are intricate, tough, and use less material.

For single, solid pieces, injection molding does the trick. But it breaks down when lattices are introduced. Machining can work, but the cost is prohibitive when you need to remove material from multiple angles.

Additive wins the day, especially when used with the AI-driven technologies mentioned above. Paired together, they create reinforced parts and assemblies with minimal weight and material costs. That ultimately saves you money both in the creation of new parts and in support down the road.

Lattice structures can provide a lightweight solution to a bulky part, saving weight without compromising strength.

Buy Creo Today

Creo is available for purchase online today. Visit the store to explore Creo suites and packages.

Buy NowTry It for Yourself

Those are the top 10 big ways additive manufacturing drives higher quality products and creates more vocal fans of your products and services. Entering the additive game is easier and less expensive than you think. Ready to learn more? Contact a Creo representative today!

Innovate Faster With Additive Manufacturing

Innovative designs in less time. Optimize and validate your designs, then run a print check—all in one environment.

Learn More