Aaron Shaw joined PTC in 2013, currently he is the Senior Manager, CAD Demand Generation. He is responsible for the CAD marketing strategy and execution worldwide. He enjoys playing golf, eating spicy foods, reading, traveling, and rooting for all Boston teams. Aaron is a graduate of Penn State, you can follow him on Twitter @AaronEShaw.

Simulation and analysis are invaluable for finding potential problems with a design. But what happens when a feature, like a weld, isn’t recognized by the simulation? Now with Creo 4.0, welds on sheet metal parts can be created as solids and measured, simulated, and analyzed. Here’s how:

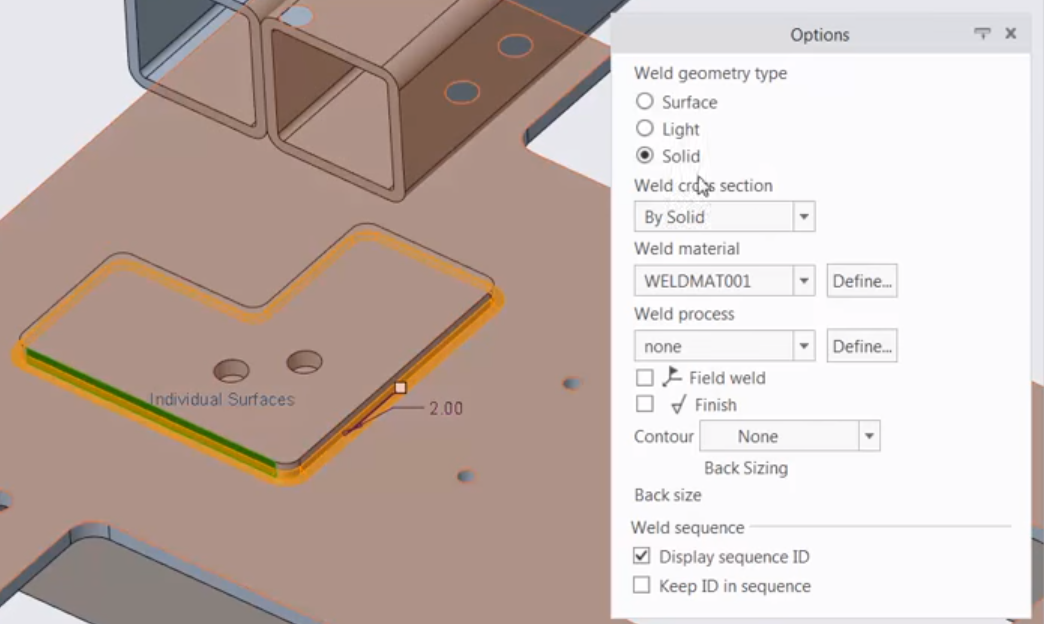

Create a Solid Weld

The process is simple, and hasn’t changed much.

- In the Insert group on the Weld tab, click a weld type: Fillet, Butt or Plug/Slot.

- Select references to create solid welds.

- Click the Options tab.

- Select Solid for the geometry type.

Selecting the Solid geometry type when creating a weld.

Measure Between a Weld and Another Solid

Now you can interact with the weld just like any other solid. For example, you can measure from the surface, edge, or groove of the weld:

- In the Measure group on the Analysis tab, click Measure and then select Distance.

- For this example, we’ll select the surface of the weld.

Measuring the distance between a weld surface and an edge.

- Select an edge of another solid on the model.

When it’s time to run a simulation, you can be confident that the weld will be treated like any other solid.

Watch the Demo

You can see a brief demo of these tips in the video below.

To learn more, read the PTC Creo Help Center page, Solid Weld.

The Best of Creo 4.0

You'll find Creo 4.0 packed with breakthrough capabilities—on top of hundreds of core enhancements. Download The Best of Creo 4 today to make sure you discover “best of the best,” then link to some quick “how-to” articles and videos, so you can make the most of Creo 4.0 and start designing smart.