Vinod Arekar is a service supply chain expert at PTC and as a Fellow he leads strategic initiatives overseeing several accounts to ensure success. Vinod’s strategic thinking and experience have helped bring the concept and application of Service Simulation to PTC. This and other innovations have helped propel Servigistics to be recognized as the industry leading service parts optimization solution. Vinod is a popular presenter at the annual LiveWorx event from sharing exciting success stories together with the clients with which he collaborates.

Performance-Based Logistics (PBL), by its very nature, is a way to align the OEM service provider's interests and their customers' interest. In the absence of PBL, equipment support is provided on a transactional basis where poor reliability leads to increased need for spares and thus more revenue for the service provider. At the same time, their customers suffer from a loss of productivity due to frequent need for spares. With PBL, the service provider is selling equipment performance rather than spare parts and has the incentive to improve service by various means, including improving reliability. In the past two decades, PBL has been the preferred sustainment strategy and priority within the Department of Defense to deliver product support solutions for the Warfighter1.

The Challenge of PBL

Tenets of PBL, originally defined by the University of Tennessee2 and adopted by OSD, highlight the importance of measurable and manageable metrics that accurately assess service providers’ performance and incentives tied to it. Common metrics include part availability within a certain amount of time and backorder age with different targets by item priority. While intuitive and necessary, these metrics don’t have theoretical formulas and, lead to guesswork in managing the PBL program. The amount of risk to both parties increases over the period of performance as the service provider reacts to changes in ground reality. As in other industries that deal with significant uncertainty, Monte Carlo simulations are necessary and recommended best practices to study, evaluate, and manage PBL contracts.

The Best-in-Class Approach

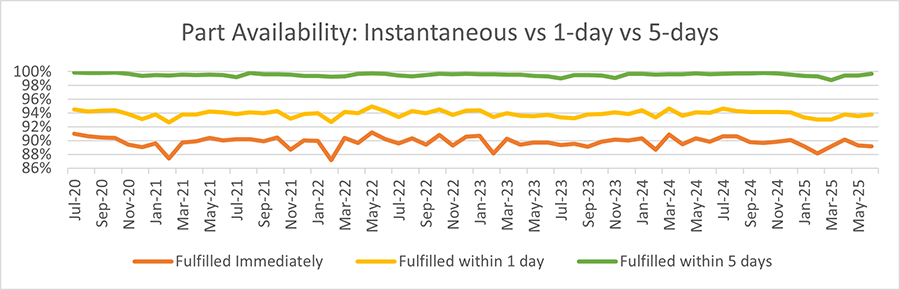

PTC’s Servigistics solution is the only enterprise-level service parts planning solution with full PBL capabilities built with Monte Carlo simulations of real-life supply chains. With fine-grained simulation, you get detailed information about how many demands you are likely to miss and how long, laying the foundation for the cash flow model. The details allow computation of penalties for not meeting targets and incentives for exceeding them over the entire period of performance of the PBL contract. See figure 1 below.

Figure 1: Part availability at the time of demand, within one day and within five days

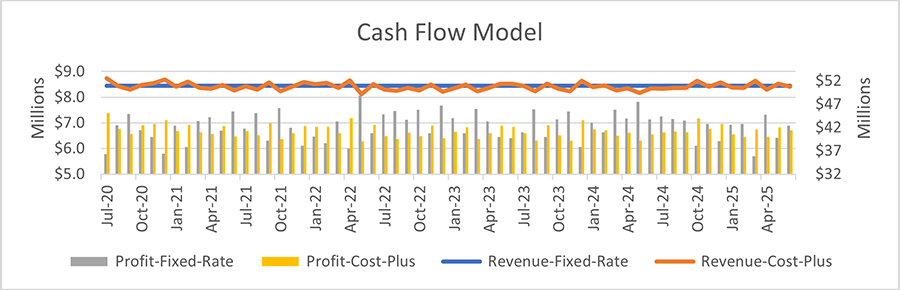

In this example, the target is to meet 90% part availability within 24 hours and 100% within five days. There will be a penalty if a demand is not fulfilled within 24 hours, an additional per-day penalty if it is not fulfilled within five days, and an incentive if part availability exceeds 92%. The level of detail in the simulation results is necessary to calculate the amount of penalty and incentive that would affect cash flow over the period of performance. Figure 2 shows the cash flow model, which considers the cost of initial provisioning, inventory holding cost, procurement and repair costs, the penalty for missing targets, and incentives for exceeding target metrics. The cash flow model shows the profitability of the contract with two revenue model options, and we see that a fixed monthly revenue model works better than the cost-plus model.

Figure 2: Cash flow model for a chosen penalty/incentive structure, with different revenue options

Servigistics enables the service provider to understand the risk and reward calculus and helps them make an informed decision in negotiating and managing a PBL contract. Sensitivity analysis based on what-if scenarios provides guidance and a basis for tuning the supply chain to create a win-win situation for the service provider and the customer.

Continuous Improvement

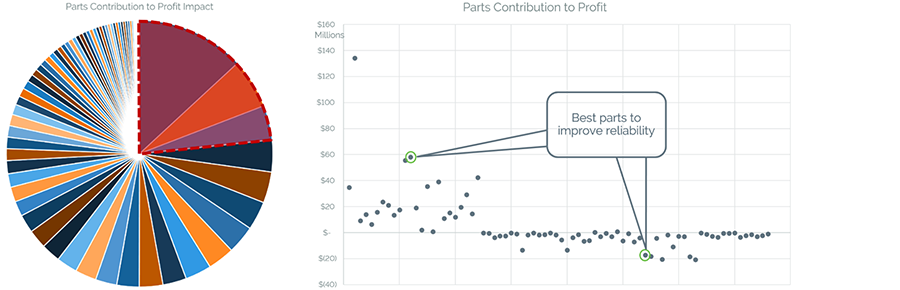

The variable and uncertain nature of demand and supply, combined with constantly changing real-world conditions, mean that continuous improvement is required even in best-managed PBL programs. The COVID-19 pandemic sent shockwaves through all global supply chains and brutally reminded service providers of the importance of the ability to handle supply chain disruptions. There are risks involved with supplier performance issues and opportunities to improve reliability to reduce equipment downtime. Risk and improvement opportunities need to be quantified, so the mitigation strategy can be targeted to specific parts. Running Monte Carlo simulations on various scenarios provides valuable intel and a way to analyze the impact of supplier performance and reliability improvement. Figure 3 shows how much of the profit is at risk due to supplier performance. While suppliers of all parts are contributing to the $51M risk, improving the performance of the top 3 parts would take away nearly a quarter of the risk.

Figure 3: Profit at risk due to supplier performance ($51M total)

Figure 4: Contribution to profit by different parts

Figure 4 shows the contribution of each part to the profit. Analyzing the reliability improvement scenario identifies two parts where a 20% improvement in reliability will increase profit by $53M. The biggest bang for the buck is not necessarily in the most profitable or most frequently needed part, it is based on how well the part performs on the PBL contract terms.

PBL Delivers Powerful Win-Win Outcomes

PBL contracts transform the transactional nature of service parts business into a collaborative approach where the OEM service provider and the customer work toward a common goal of providing the required level of service at the lowest cost. The key metrics of PBL contracts are nearly impossible to plan to, yet critical to cash flow and, therefore, the success of the contract for both parties. Servigistics’ Monte Carlo simulations-based approach helps model real-life metrics and cash flow, leading to collaborative contract terms selection that creates a win-win situation for both parties. PBL contracts incentivize reliability and other continuous improvements. Servigistics’ methodology provides unparalleled ability to evaluate the financial and service impact of the improvements and focus on specific parts delivering the best ROI improvement. Servigistics empowers OEM service providers and their customers to develop and manage PBL programs that unlock the immense value they were intended to.

References

[1] PBL Guidebook: A Guide to Developing Performance-Based Arrangements. Release 2016, US Department of Defense

[2] The Tenets of PBL Second Edition, A Guidebook to the Best Practices Elements in Performance-Based Life Cycle Product Support Management. University of Tennessee and Supply Chain Visions (2012).

Unlock the True Potential of Performance-Based Logistics.

With powerful enabling technology, Performance-Based Logistics (PBL) programs have the unique potential to deliver high equipment availability at the lowest cost.

Download Now