Cat McClintock contributes to the Creo and Mathcad blogs for PTC. She has been a writer and editor for 15+ years, working for CAD, PDM, ERP, and CRM software companies. Prior to that, she edited science journals for an academic publisher and aligned optical assemblies for a medical device manufacturer. She holds degrees in Technical Journalism, Classics, and Electro-Optics. She loves talking to PTC customers and learning about the interesting work they're doing and the innovative ways they use the software.

What is CAD software?

Computer-aided design (CAD) is software that product developers use to create digital 2D drawings and 3D models. These designs are typically used to show objects that will later be manufactured and delivered to customers.

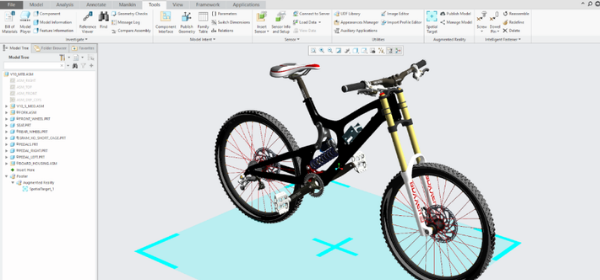

A model of a mountain bike designed using CAD software

Why use 3D CAD?

First, a story. I once delivered a secret CAD software demonstration in the backroom of a custom car garage from a cable television show. We delivered the demo in secret because the celebrity star of the show insisted that all their design was done by hand.

Without computers, products are typically represented by pencil drawings, often showing each part at multiple angles. Even today, some engineers still use 2D CAD drawings for some applications.

Near the end of the demo, the celebrity star walked in on us. Although clearly not happy about seeing a computer or CAD software in his shop, he was actually very polite. Nonetheless, his team passed on CAD.

A few years later the garage closed.

In my experiences in CAD training, consulting, and sales, that was my most memorable experience with an anti-CAD company, but far from the only one. All these companies placed themselves at a competitive disadvantage and hurt their efficiency and productivity. Let’s look at the ways you can benefit from using CAD software.

It’s easier

If you’re not using a 3D CAD modeler for design, most likely you are sketching on paper or using old-fashioned 2D drafting techniques. It takes effort, training, and significant thought to represent 3D objects in 2D, and to look at a standard six-view layout and convert it to a 3D object in your mind. With CAD, you can create the 3D object, and then zoom in, zoom out, and spin it around to gain complete understanding of what this object is. Quite simply, 3D is easier.

It’s faster

This is why the team from that reality show wanted to see a CAD demo. They could not generate design alternatives fast enough by hand, and they wanted to see the effect of making changes to shapes and dimensions immediately. When you combine computing power with modeling, productivity skyrockets.

It’s less work over time, too

Once you create an object in CAD, it’s available to leverage over and over again. There are a couple ways in which you can do this.

First, you can generate libraries of standard components, such as fasteners, electronics, and other commercial off the shelf (COTS) components, that can be easily placed in your designs.

Second, you can take your existing designs and use them as the basis for the next generation product, saving yourself incredible time and effort.

It can be used conveniently downstream

The CAD models that you create are not the end point of your design effort; they’re the beginning. Your CAD models can be used for:

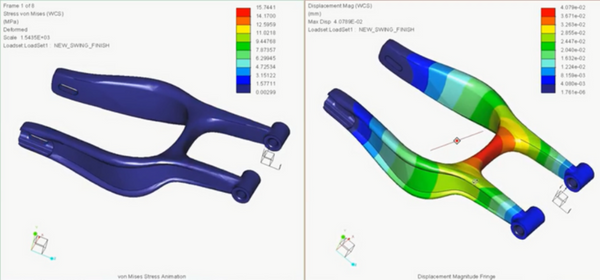

Simulation. People can perform analyses including structural, thermal, mechanism, computational fluid dynamics (CFD), and more on the digital model. This isn’t a substitute for real-world testing, but verifies you’re performing the right tests. You save time and resources that would have been wasted on unnecessary physical testing.

A computer simulation tests the strength of a 3D model when forces are applied at different points.

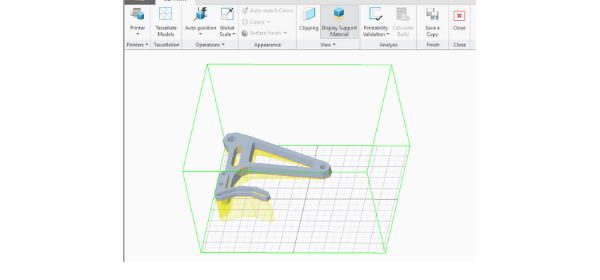

Manufacturing. After you design your product, you need to make it. CAD models help you define CNC toolpaths for machining, molds, castings, sheetmetal bending and punching routines, and 3D printing supports. Plus it can help in the generation of manufacturing process plans and work instructions.

Many 3D printers (additive manufacturing) produce parts and the supports needed to hold them in place during printing. CAD systems can help find the best locations for these supports.

Enterprise planning and operations. Your CAD assembly’s product structure generates the Bill of Materials (BOM) used in planning, procurement, and inventory. Viewables of the model can be used in sales and marketing, and anyone in your organization can examine your models without having to install the native authoring software. And just like your CAD helps generate manufacturing and assembly information, it can also be leveraged to generate technical illustrations for customer documentation and maintenance and repair instructions.

A 3D CAD model is rendered to show off its curves and smooth surfaces. This can be used to sell the design before it’s ever manufactured.

Living on the leading edge of technology

Product development continues to move forward, especially for CAD. Advances like augmented reality, Internet of Things (IoT), and topology optimization are only available to designers who create their models in 3D CAD. These technologies have given products and companies a significant competitive advantage in the market. Who knows what other leaps will be available in 5, 10, or 20 years, but we do know they will be enabled by CAD.

People have literally said to me that paper and pencil were good enough for the Wright brothers, so they don’t need CAD. If given a choice, Orville and Wilbur surely would have opted for a computer and engineering design software. If you’re not using CAD, you’re working harder and slower, generating fewer results. By embracing CAD, designers and engineers are creating better products faster and easier than ever, and their products continue to reach the market every day, unlike the design group from that reality show garage.