Preeya is a Content Marketing Specialist with expertise in crafting compelling stories about disruptive technologies across diverse industries. She is passionate about developing engaging, insightful content that empowers readers and decision-makers with the knowledge they need to drive innovation and success.

Manufacturers are waking up to a new reality: sustainability has vaulted to the forefront of their business initiatives. In fact, a recent report (CIMData eBook) demonstrates that consumers not only prefer sustainable products but are willing to pay a significant markup to purchase them. As a result, companies are facing social and competitive pressure to meet the market demand. Organizations who may have previously resisted the perceived cost of sustainability are now scrutinizing the environmental impact of their products and processes. This includes examining their business and finding new ways to make their products and operations more sustainable.

And as the public understanding of sustainability improves, companies are discovering that a sustainability talk track no longer satisfies the market. Today, sustainability requires more than a slick advertising campaign or charitable donations to green causes—efforts must be credible, documented, and driving measurable results. In addition to sustainable products, operational sustainability improvements often reduce waste, scrap, utility, and materials costs. Sustainability may be a challenging pursuit, but it offers a wide range of benefits that manufacturers can no longer afford to overlook.

To meet these challenges, companies must look across operations and entire product lifecycles to pinpoint where efficiencies can be gained. For organizations just beginning to undertake this effort, they should be focusing on three pillars of sustainability: environmental, social, and economic. When reviewing the product lifecycles, manufacturers shouldn’t be surprised that sustainability should be introduced at the beginning of the lifecycle. The product design and engineering phases are ripe for sustainability improvement.

What does sustainability mean in product design?

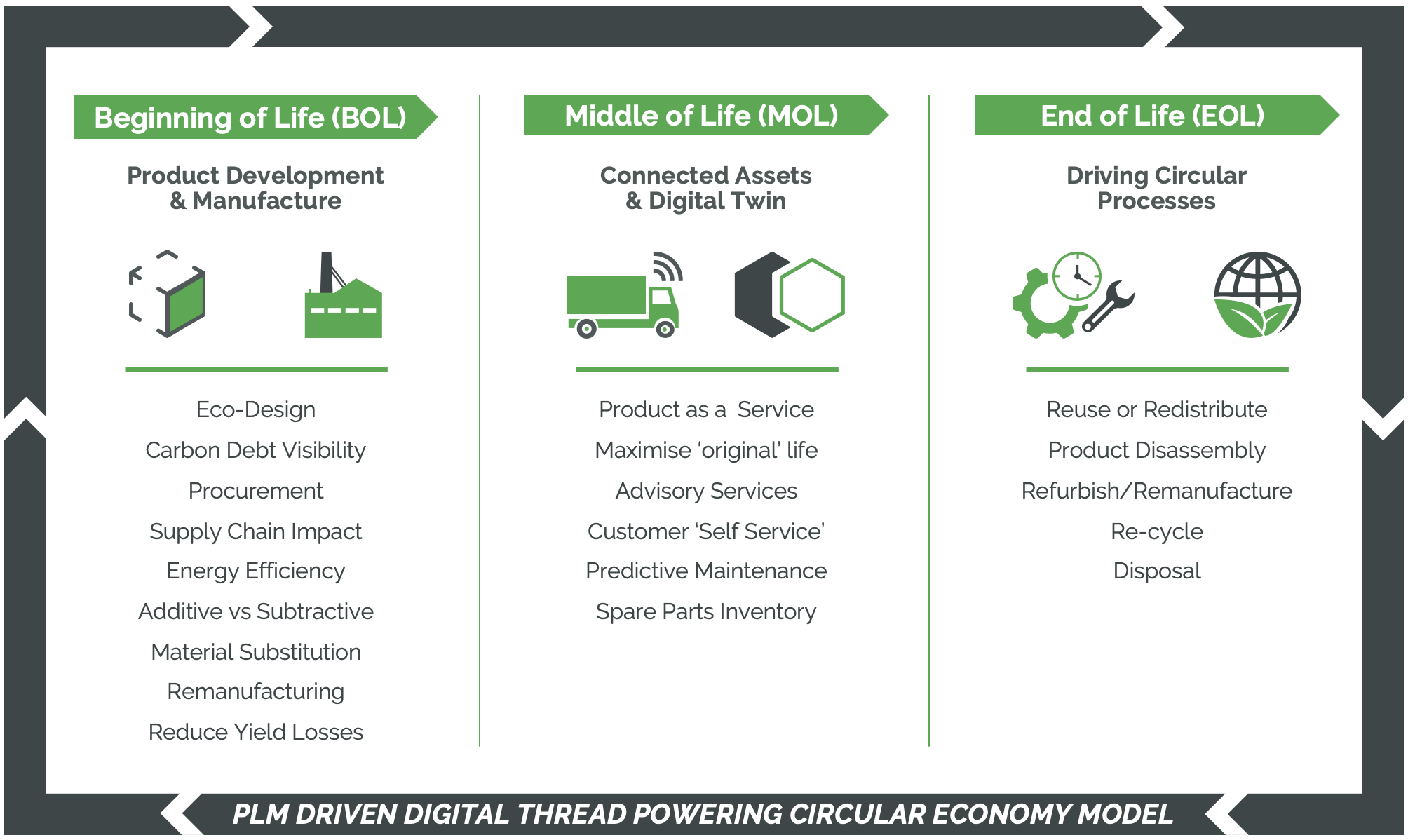

When looking at a product’s lifecycle, we can see how a pattern of sustainability forms. Following a circular economy model, products should be designed to be reused and recycled. Every product goes through the product design, material sourcing, manufacturing, operation and service, and end of life stages. Astute manufacturers will recognize the impact that initial design decisions have on each stage that follows.

During the engineering and design phase, a sustainably informed team follows the circular economic model. As they map out ideas and create prototypes, there’s ample room for sustainable adaptations, from reducing emissions to making consumables recyclable and more efficient. By addressing how efficiently a product progresses through its lifecycle, designers and engineers are dictating how a product will impact the environment.

The circular economy model guides a product through its entire lifecycle. Product lifecycle management (PLM) solutions help aid and organize the vast amount of product information.

The circular economy model guides a product through its entire lifecycle. Product lifecycle management (PLM) solutions help aid and organize the vast amount of product information.

Why is sustainable product design important?

The decisions made during the design and engineering stage are critical to determining whether a product will be sustainably resourced, built, distributed, used, serviced, and disposed of. Much of a product’s CO2 footprint is determined during the design phase. Considering that, product design’s role should be front and center in any manufacturer’s sustainability strategy. With expanding global regulations and increased interest from both investors and consumers, sustainability has moved to the forefront of business conversations, and practicing sustainability has become imperative for many companies to stay competitive.

Global regulations

Manufacturers need to meet specific requirements to be approved and/or certified as a green organization. In the case of the European Union, regulations like the European Directive on Waste from Electrical and Electronic Equipment (WEEE) and the Restriction of Hazardous Substances Directive (RoHS) offer strict guidelines to companies wishing to sell electrical and electronic equipment. These companies must fulfill product compliance requirements and support end-of-life management in each country. That means providing take-back, recycling, and recovery solutions to their supply chain stakeholders and end-user consumers. The amount of information necessary to meet these regulations is substantial. Regulations like these are only beginning to appear; manufacturers can expect the volume of these regulations to increase and address every aspect of a product’s lifecycle. Again, upfront sustainable product design will determine how effectively these downstream regulations can be met.

Consumer and Investor Demands

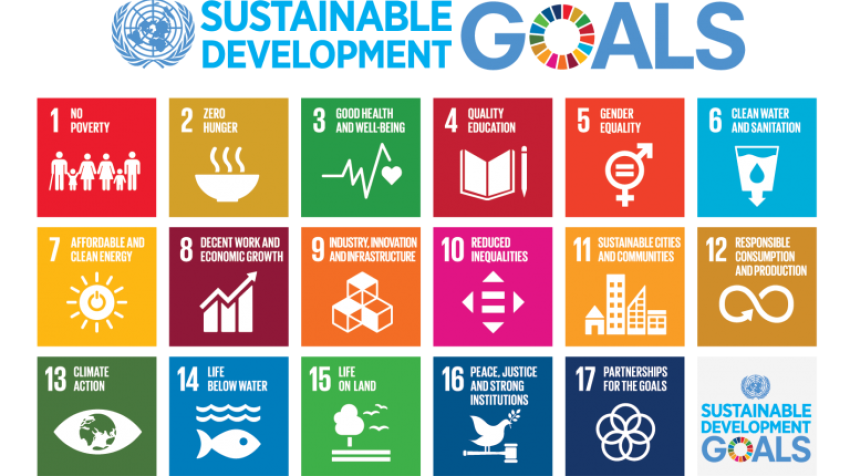

62% of consumers now say they’re willing to change their purchasing behavior to help reduce negative impacts on the environment (CIMData eBook). Understanding what consumers and investors value is critical to ensuring competitive success. One resource for organizations is the list of UN Sustainable Development Goals (SDGs). The SDGs offer companies free market research into aspects of sustainability that their customers and investors care the most about.

Staying Competitive

By staying on top of shifting global regulations and increasing pressure from consumers and investors, manufacturers are remaining competitive. A survey done by the UN Global Compact in 2021 found companies that built sustainability into their “DNA” delivered more financial value and broader stakeholder impact. And those companies with the most embedded sustainability practices outperformed their peers by 21% on both profitability and positive sustainability outcomes.

Four Ways to Execute Sustainable Product Design

Having trouble identifying where to start? These four principles help illustrate the steps that can be taken in the design stage to accelerate your sustainable business goals.

Source sustainably produced or recycled materials for environmental good

Sustainable materials refer to materials that don’t negatively impact the environment during production, use, or disposal. When designing a product, think: where am I getting these materials from? Perhaps the materials are sourced from a company with their own sustainability initiatives or from a company that strictly uses recycled materials. Even sourcing local materials helps! By utilizing local materials, organizations end up cutting down on transportation costs and as a result, product lifecycle CO2 emissions.

Design products for reuse and recycling

By following a product through its lifecycle, we see how the product forms—with raw materials, design sketches, and prototypes –and how it ends—in a landfill, reused, or recycled. Looking through a sustainable framework, it’s important to consider the ways in which we can shift a product’s end of life.

Consider the type of materials included in your product and start asking questions. Are these materials able to be recycled or reused? Materials like steel, aluminum, PET plastic, and HDPE plastic, for example, make good contenders for easy recyclability. Is your product made up of multiple types of materials or one material? A product made up of one standard material is easier to recycle or reuse when compared to a product made from multiple or blended materials. It’s also cost effective to reuse scrap and waste. Is your product built to be easily taken apart? If your product is made from a wide array of materials, it should be designed so that it can be easily disassembled and the materials sorted, recycled, and reused.

Track sustainability efforts with Product Lifecycle Management tools

The most important part of managing a product’s lifecycle is managing all the information that comes with it. With any product, you want to be able to track usage data and feedback when creating the next generation of products. Product lifecycle management (PLM) solutions are incredibly helpful when it comes to organizing, sharing, and drawing meaningful conclusions out of complex data. Similarly, PLM can help with managing sustainability data. PLM can help with tracking metrics like CO2 emissions, average time until product retirement, and how sustainable the materials/suppliers are. By enabling the seamless sharing of information and building a digital thread across an enterprise, PLM helps designers and engineers build a better, more sustainable product for generations to come.

Build premium products that last longer

The longer a product lasts, the longer it stays out of a landfill. Therefore, designing for durability significantly extends a product’s lifecycle. Product durability, in turn, lessens the need for replacements, repairs, or waste. The result is a higher-value product and brand equity.

How Real-World Industry Leaders are Embracing Sustainable Product Design

Hewlett-Packard (HP), a leading global provider of software, technologies, and products and Vestas, a wind energy solutions leader, have both realized how imperative the sustainability mission is. Discover how both companies are executing their short-term and long-term goals.

|

|

||

| Vision |

HP Printers has a 2030 Sustainability Impact Vision to become the world’s most sustainable technology company. The vision is based on three pillars: planet, people, and community. | Vestas’ vision is to deliver green energy solutions all while minimizing data complexity and maximizing sustainability across the value chain. |

| Strategy |

HP Printers is focusing on product circularity and reusability by reducing materials, keeping materials in use longer, and minimizing deforestation. To track year over year progress against their targets, HP Printers collects information from their products, services, and supply chain regarding materials intensity, product usage, repairs, etc. They collect all this information in PTC’s PLM solution, Windchill. This way they can have all their data together in one database to make better decisions. |

Vestas was named the most sustainable company in the world—a testament to their existing achievements and their ongoing progress in ensuring sustainability in everything they do. |

| Goal |

HP Printers’ goals include:

|

Vestas’ goals include:

|

Sustainable Design Certification

If your organization is exploring an increased commitment to sustainable design, there are several certifications that can be pursued. PLM-supported design practices will benefit and accelerate efforts to earn these certifications.

Cradle to Cradle (C2C)

The C2C certification is the global standard for measuring the environmental and social sustainability of a product. Using five distinct categories: material health, product circularity, clean air/climate protection, water/soil stewardship, and social fairness, the C2C examines how an organization takes these considerations into account during their product lifecycle.

ISO 14062

The ISO 14062 standard regulates concepts and current practices related to sustainable product design and development. This standard is relevant when creating industry-specific documents.

Conclusion

The time for adopting sustainable manufacturing practices is now. Sustainability impacts the entire value chain, offering tremendous financial value, and competitive advantage. It’s possible to do right by the planet, the people impacted by your operations and products, while still driving value and improving profits. But it is a serious undertaking that requires strategic planning, substantial process changes, and organizational change efforts to alter the “DNA” of your extended enterprise. There is a lot of work to do, but companies are getting out what they put into sustainability initiatives. One thing is certain—you cannot afford to wait.

Download this eBook from analyst firm CIMdata to learn how the PLM Economy offers the tools and process support needed to build a solid foundation for sustainability program success.