Cat McClintock contributes to the Creo and Mathcad blogs for PTC. She has been a writer and editor for 15+ years, working for CAD, PDM, ERP, and CRM software companies. Prior to that, she edited science journals for an academic publisher and aligned optical assemblies for a medical device manufacturer. She holds degrees in Technical Journalism, Classics, and Electro-Optics. She loves talking to PTC customers and learning about the interesting work they're doing and the innovative ways they use the software.

According to Statista, in 2017, the number of smartphone users in Spain will reach 30.3 million. By 2021, the number will grow to 34.3 million. That means engineers and product designers across Spain will need to produce innovative mobile devices quickly and efficiently.

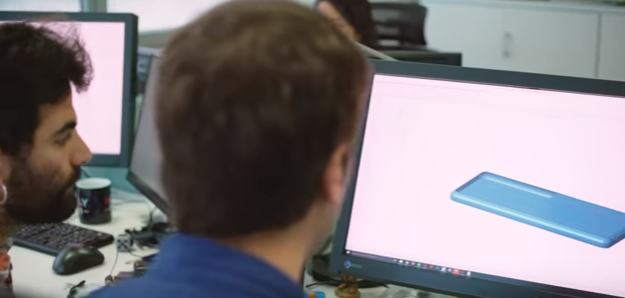

Design prototypes at BQ

Enter BQ, the third largest manufacturer in Spain. BQ designs and develops mobile phones (as well as 3D printers, tablets, and e-readers). Though technically an “engineering company,” BQ says it manufactures its mobile phones to ensure the products meet the needs of clients. Needless to say, “time to market” is crucial.

The Design Process

Once product plans are in place, the team at BQ defines the components for each device. An “advanced assembly unit” quickly creates the shells of those components. The team then selects the colors and materials for each device. Finally, once everyone agrees on the design, technical development begins.

Designers collaborate on phone model at BQ

Quicker Designs Need Stronger Tools

Previously, BQ used non-parametric tools to design their 3D models. Direct modelers like these make sense for creative work, as they don’t impose constraints and free up designers to follow their imaginations as they work. But there’s a tradeoff: any company that wants to reuse and modify designs down the road typically needs a traditional parametric modeler to ensure design intent stays intact.

BQ now gets the best of both with Creo. By adding Creo’s combination of direct modeling and parametric software, the company enjoys the exactness of one, while still enjoying the more open benefits of the other. That means they can quickly leverage the best of their previous designs, without compromising innovation. And that means new, cool designs get to market quickly.

Windchill also plays a role, since sharing component data gives BQ greater control over the development process.

“In the future, our plan with PTC is to set up Windchill in our offices in China to give us full control of the product development cycle,” says Julen Pejenaute, product designer. “This will ensure our latest designs are controlled in the same way in both Spain and China.”

Watch this video see BQ’s design process up-close:

Download the Free E-book

Does your current 3D CAD software give you the power to do your best design work? Find out how Creo can help you create higher-quality products (like a smartphone) in less time. Download our FREE e-bookTop 7 Reasons to Design with Creo to learn more.